guess you like

BHX Combined-Flow Closed-Circuit Cooling Tower – Scalable, Efficient, and Low-Scaling Design

BNX Counterflow Closed Circuit Cooling Tower – High-Efficiency Industrial Heat Exchanger

ZNX Counterflow Evaporative Condenser – Compact, High-Performance Heat Rejection

ZHX Combined Flow Evaporative Condenser – Enhanced Efficiency with Fill-Assisted Heat Transfer

Cooling Coil

Drift Eliminator

PVC Fill

Fan

Spray Nozzle

V-type Air Cooler

Cooling Tower Drift Eliminator

Overview

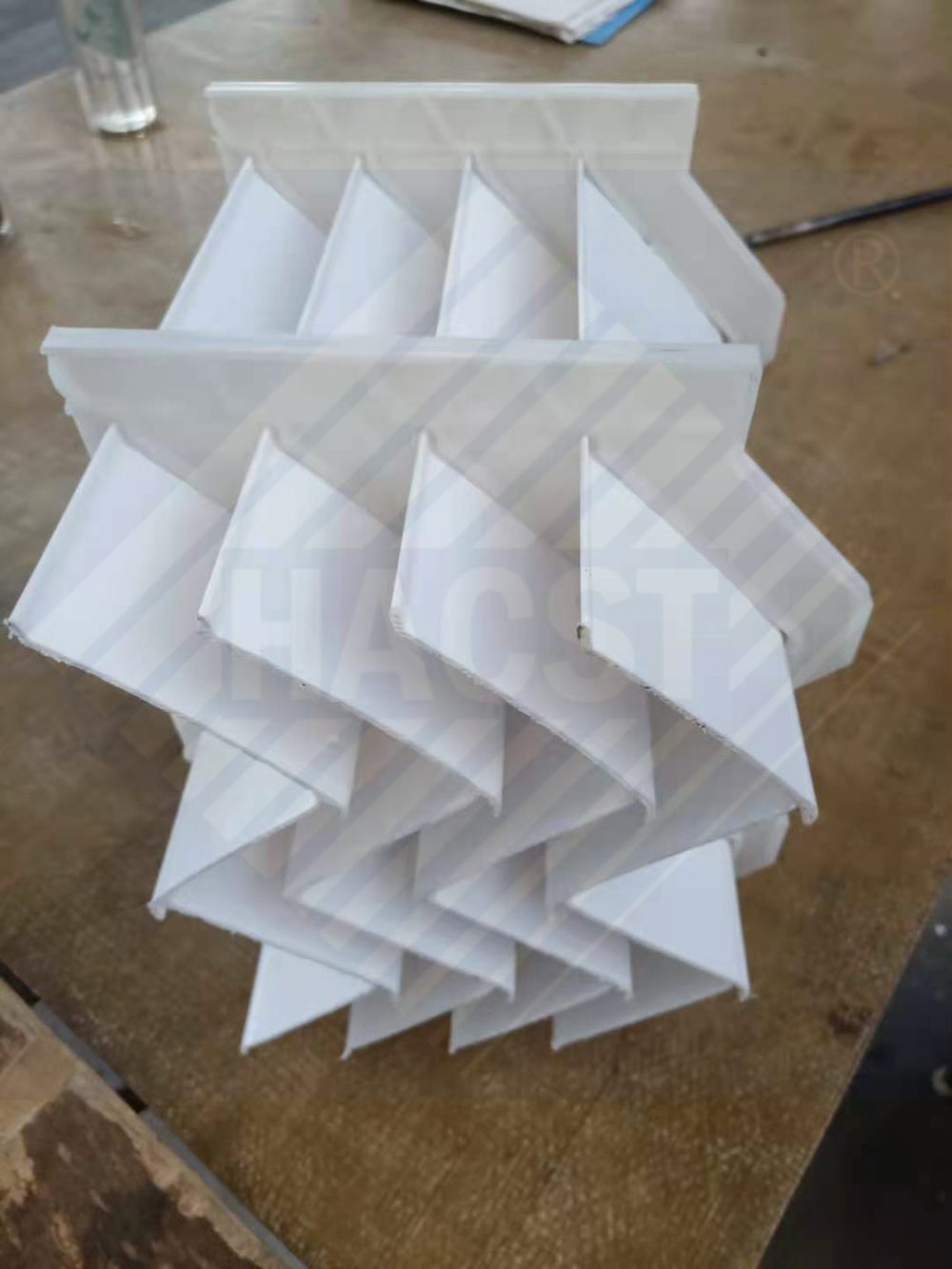

A drift eliminator is a critical component that prevents water droplets from escaping the cooling tower with exhaust air. It ensures water conservation, reduces chemical loss, and protects the environment.

Function in Cooling Towers

As fans drive large volumes of air through the cooling tower, small droplets can be carried upward. The drift eliminator forces the air to change direction multiple times, causing droplets to collide with surfaces and fall back into the basin.

Design & Performance

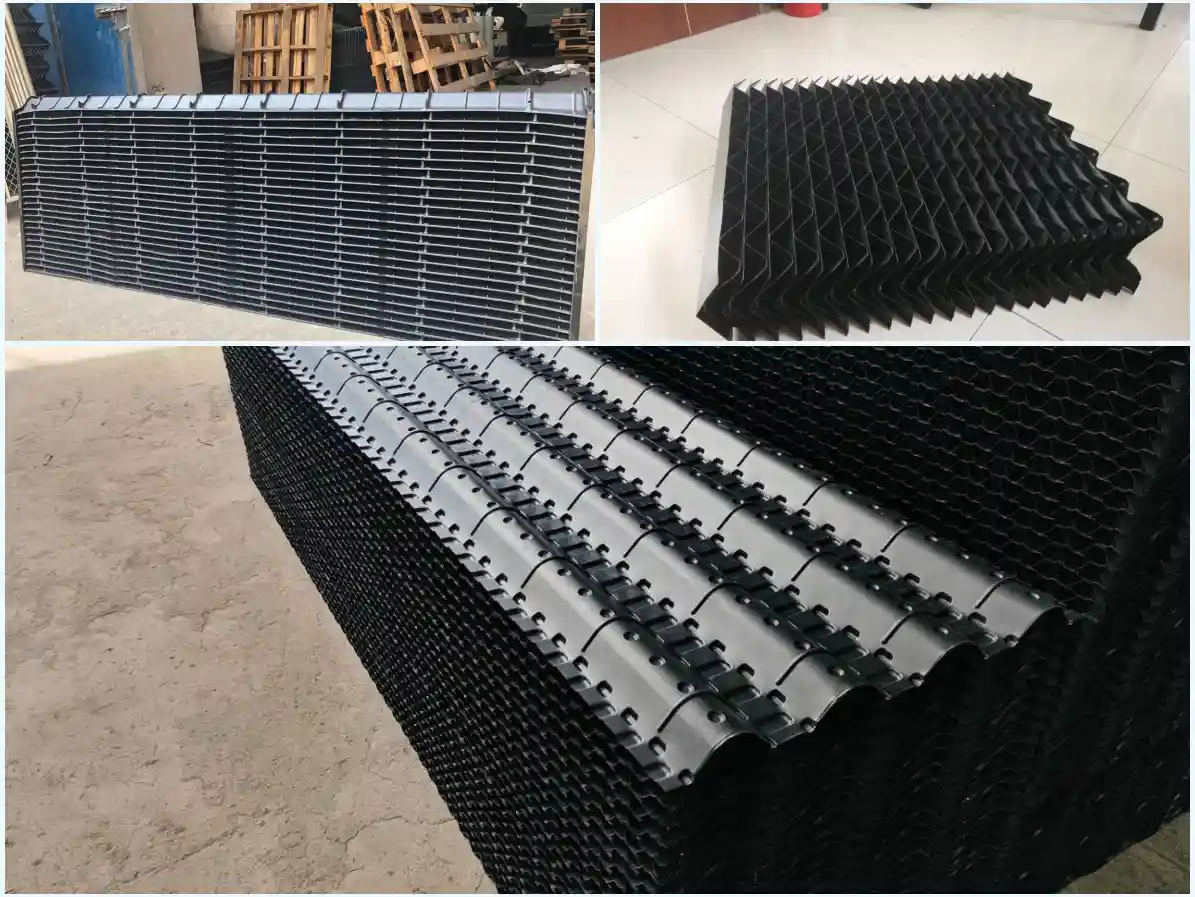

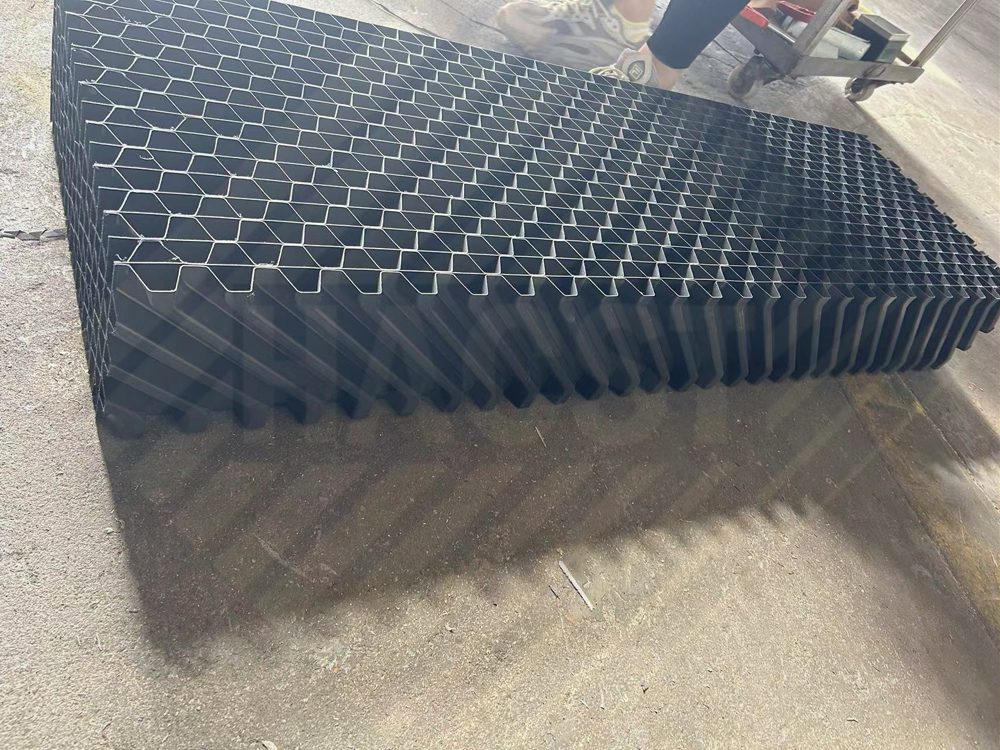

- Cellular Type: Uses honeycomb-like channels for high efficiency and compact size.

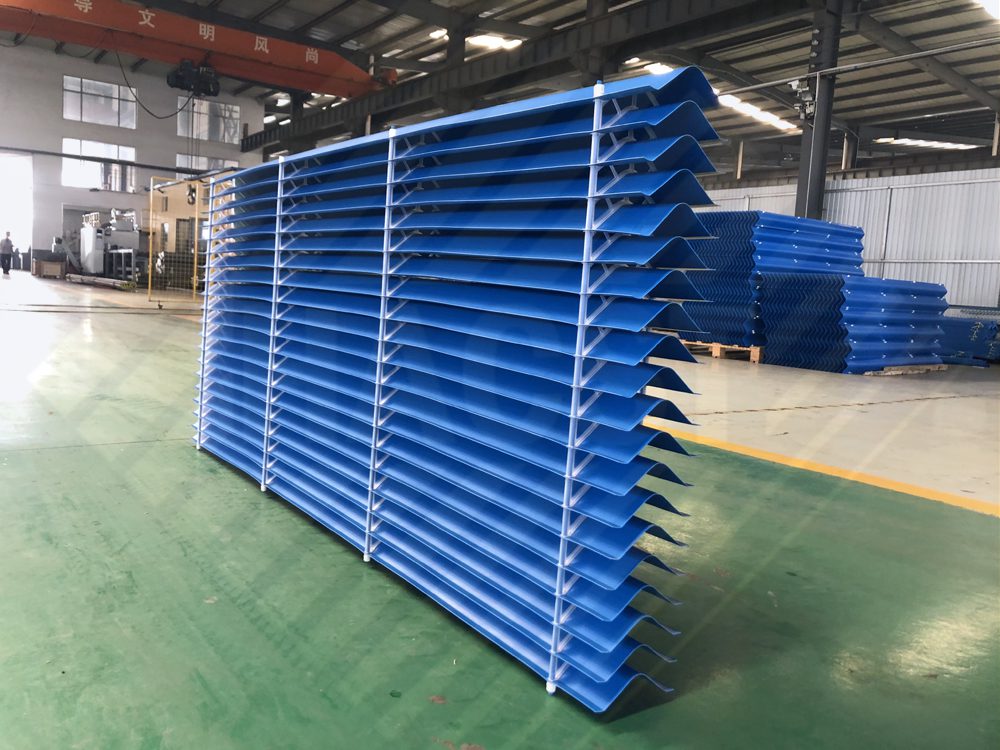

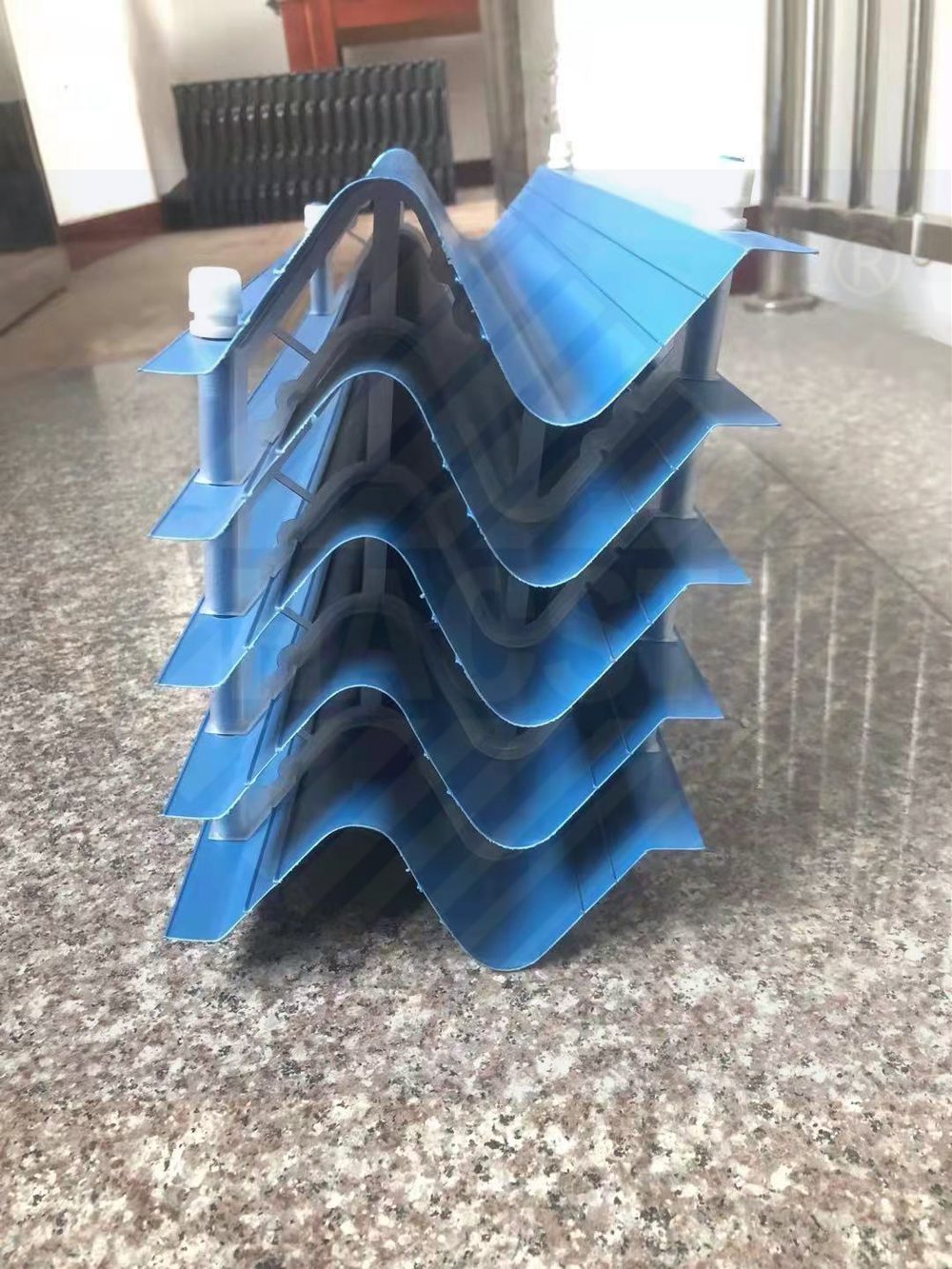

- Blade Type: Curved blades deflect air paths; suitable for large industrial towers.

High-quality drift eliminators reduce water losses to less than 0.001% of circulating flow.

Applications

Drift eliminators are used in open cooling towers, evaporative condensers, and hybrid towers to minimize visible plumes, water losses, and chemical discharge.

How to Select

- For compact factory-assembled towers → Cellular profiles are preferred.

- For large field-erected towers → Blade-type designs handle higher airflow rates.

- Material choice (PVC, PP, FRP) depends on temperature and chemical exposure.