guess you like

BHX Combined-Flow Closed-Circuit Cooling Tower – Scalable, Efficient, and Low-Scaling Design

BNX Counterflow Closed Circuit Cooling Tower – High-Efficiency Industrial Heat Exchanger

ZNX Counterflow Evaporative Condenser – Compact, High-Performance Heat Rejection

ZHX Combined Flow Evaporative Condenser – Enhanced Efficiency with Fill-Assisted Heat Transfer

Cooling Coil

Drift Eliminator

PVC Fill

Fan

Spray Nozzle

V-type Air Cooler

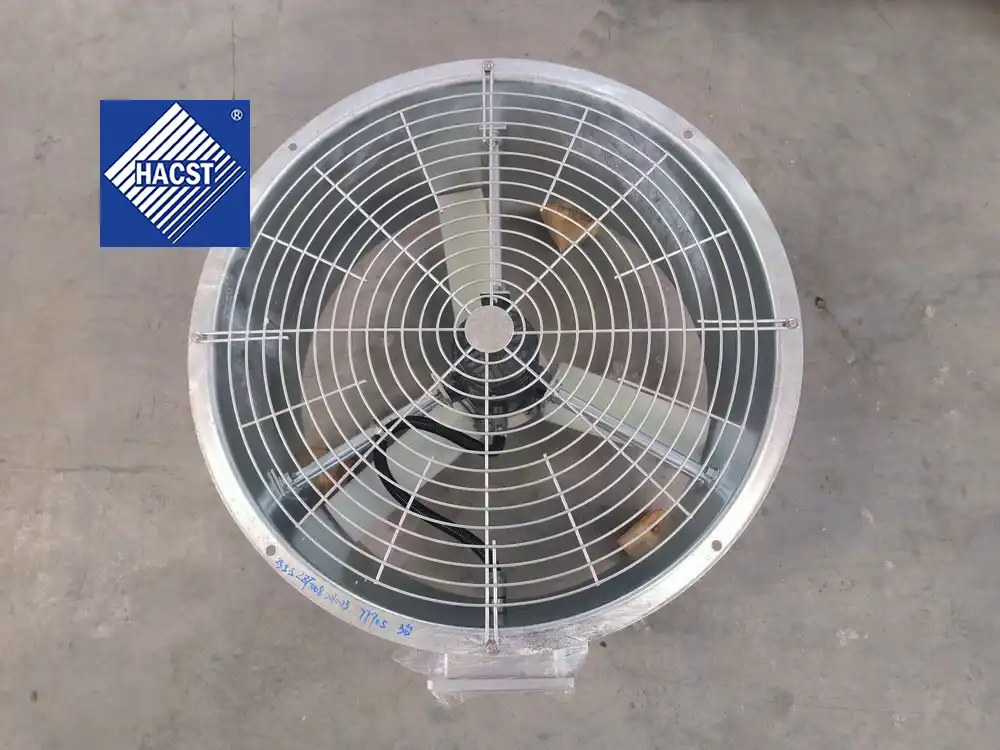

Cooling Tower Fan

Overview

The fan is the driving force of airflow in cooling towers and evaporative condensers. By inducing or forcing air through the fill or coil sections, fans enable evaporative cooling and efficient heat rejection.

Role in Cooling Towers

Fans maintain the required air velocity and distribution across the heat exchange surfaces. Their design directly impacts cooling efficiency, noise levels, and power consumption.

Types of Fans

- Axial Fans: Lightweight, efficient, commonly used in most cooling towers. Available with adjustable pitch for performance tuning.

- Centrifugal Fans: Used where static pressure is high or when low noise operation is required, typically in indoor installations.

Applications

Fans are used in counterflow and crossflow cooling towers, hybrid towers, evaporative condensers, and dry coolers. Selection depends on airflow rate, static pressure, and noise requirements.

How to Select

- For large industrial towers → axial fans with FRP blades are preferred.

- For urban installations → centrifugal fans reduce noise and vibration.

- Choose blade material (aluminum, FRP) based on durability and cost.