guess you like

BHX Combined-Flow Closed-Circuit Cooling Tower – Scalable, Efficient, and Low-Scaling Design

BNX Counterflow Closed Circuit Cooling Tower – High-Efficiency Industrial Heat Exchanger

ZNX Counterflow Evaporative Condenser – Compact, High-Performance Heat Rejection

ZHX Combined Flow Evaporative Condenser – Enhanced Efficiency with Fill-Assisted Heat Transfer

Cooling Coil

Drift Eliminator

PVC Fill

Fan

Spray Nozzle

V-type Air Cooler

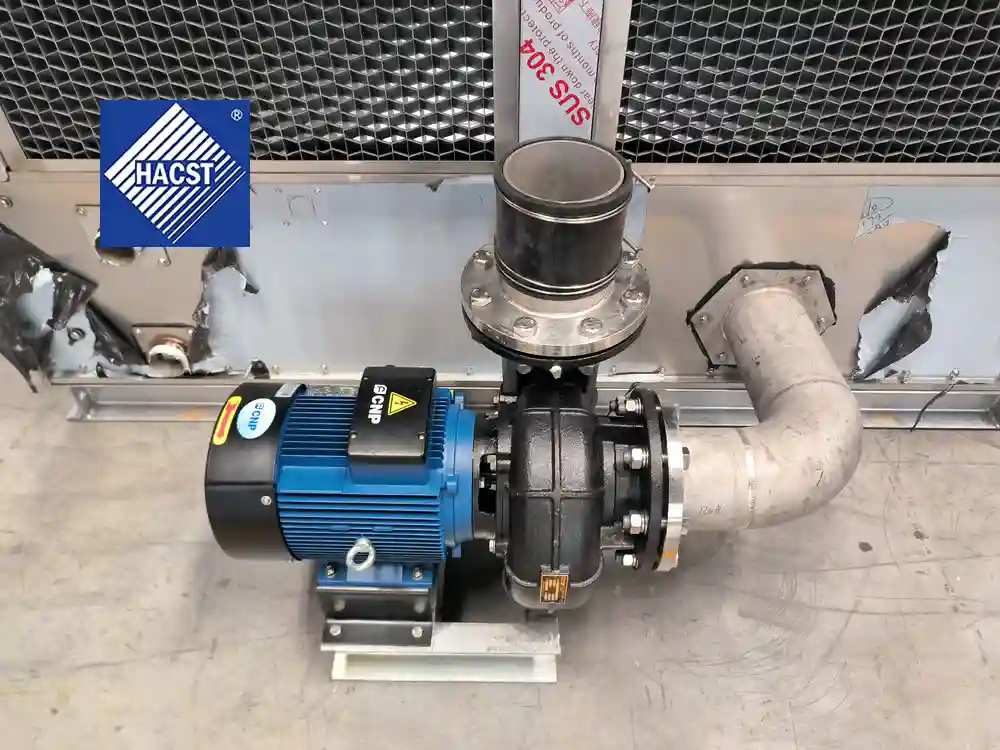

Cooling Tower Circulation Pump

Overview

The circulation pump is responsible for moving water from the cooling tower basin to the distribution system or heat exchangers. It is critical for maintaining continuous water flow and stable cooling performance.

Role in Cooling Towers

Pumps ensure water is distributed uniformly across the fill or coils. Their capacity and head directly influence cooling efficiency and system reliability.

Pump Types

- Vertical Inline Pumps: Compact, space-saving, easy to integrate into cooling systems.

- End Suction Pumps: Economical, widely used in medium-sized cooling towers.

- Split Case Pumps: High capacity, suitable for large industrial systems with high flow demands.

Applications

Cooling tower circulation pumps are used in HVAC, power plants, petrochemical industries, and manufacturing processes requiring continuous cooling.

How to Select

- Base pump choice on required flow rate and system head loss.

- Use stainless steel pumps for aggressive water chemistry.

- Choose VFD-compatible pumps for energy savings and precise control.