guess you like

BHX Combined-Flow Closed-Circuit Cooling Tower – Scalable, Efficient, and Low-Scaling Design

BNX Counterflow Closed Circuit Cooling Tower – High-Efficiency Industrial Heat Exchanger

ZNX Counterflow Evaporative Condenser – Compact, High-Performance Heat Rejection

ZHX Combined Flow Evaporative Condenser – Enhanced Efficiency with Fill-Assisted Heat Transfer

Cooling Coil

Drift Eliminator

PVC Fill

Fan

Spray Nozzle

V-type Air Cooler

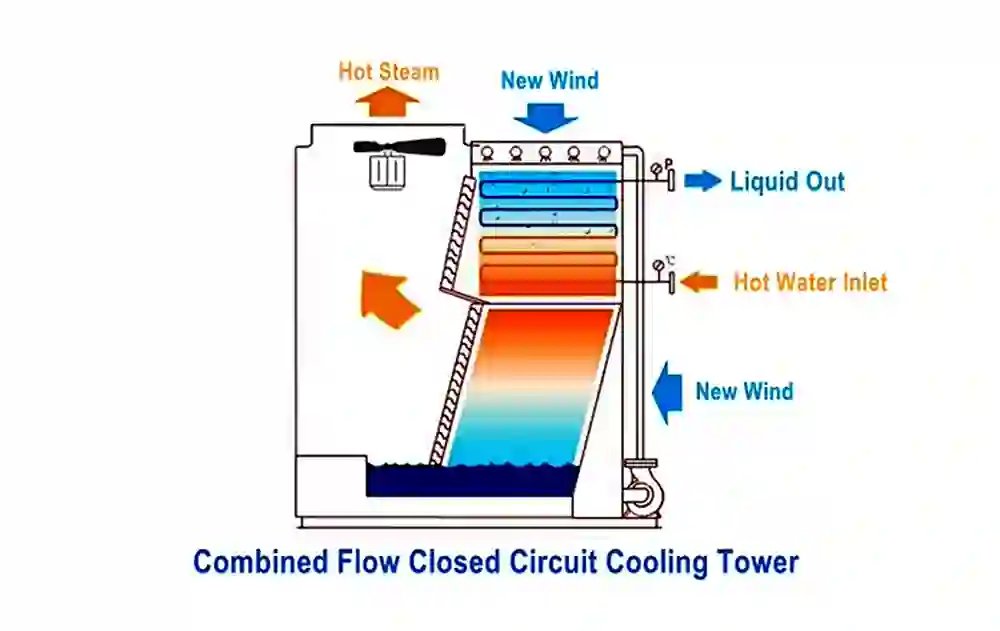

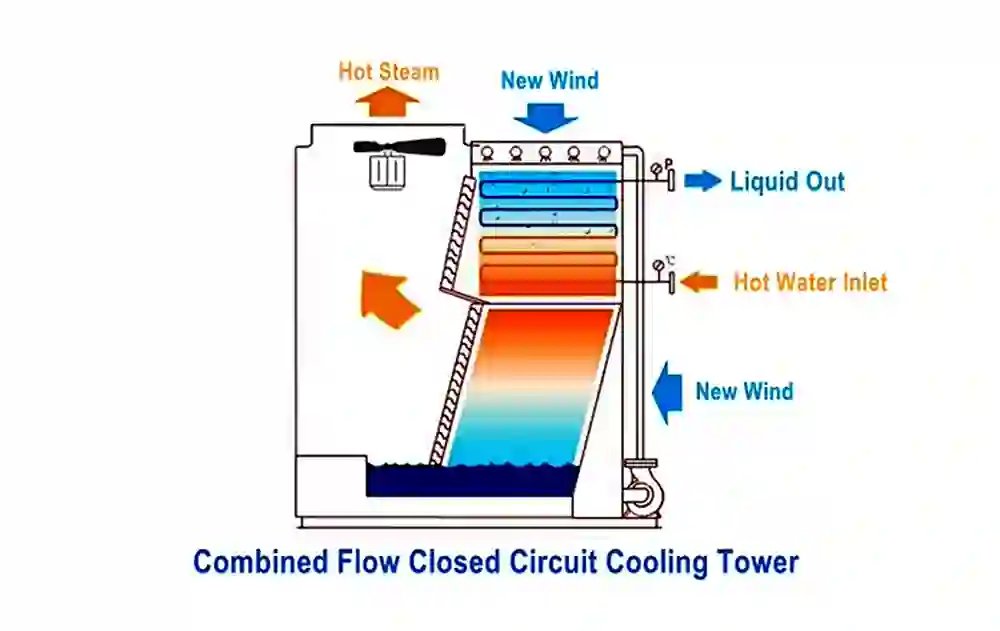

BHX Combined-Flow Closed-Circuit Cooling Tower

Product Overview

The BHX Combined-Flow Closed-Circuit Cooling Tower integrates the strengths of both crossflow and counterflow cooling technologies. By combining horizontal and vertical air intake paths, the BHX tower achieves superior thermal performance, reduced energy usage, and enhanced adaptability for a wide range of industrial cooling requirements. This makes it an excellent solution for large-scale HVAC and heavy-duty industrial applications.

Working Principle

In the BHX tower, the process fluid circulates inside a closed serpentine coil, remaining completely isolated to prevent contamination. Spray water is evenly distributed over the coil, while fresh air enters both horizontally (crossflow) and vertically (counterflow), forming a combined airflow pattern. This design maximizes heat exchange between water, air, and coil.

Heat from the process fluid transfers through the coil wall to the spray water and air. The warmed spray water is cooled as it passes through the PVC fill, where it flows in the same direction as the incoming air for efficient heat conduction. Fans discharge the heat into the atmosphere, while the cooled spray water collects in the basin, passes through drift eliminators, and is recirculated for continuous operation.

Applications

- Heavy Industry: Steel mills, chemical plants, oil refineries, and mining operations requiring high-capacity cooling.

- Large HVAC: District cooling, airports, stadiums, and high-rise building complexes.

- Refrigeration: Industrial refrigeration systems in food processing, cold storage, and petrochemical sectors.

- Energy: Power plants and renewable energy facilities requiring robust, high-performance cooling solutions.

Performance & Efficiency

The combined-flow design enables the BHX to achieve higher cooling capacity compared to single-flow towers of the same footprint. By reducing the air pressure drop, energy consumption is minimized, while cooling performance remains stable across a wide range of operating conditions. The closed-loop system ensures clean process water, minimizing fouling and scaling risks. The design also provides excellent adaptability to sites with varying environmental conditions.

Key Advantages

- Superior Heat Exchange – Dual airflow paths with coil and suspended PVC fill prevent dry spots and scaling, ensuring excellent thermal performance.

- Compact & Efficient – High cooling capacity per footprint, equipped with energy-saving axial fans, reducing overall operating costs.

- Easy Maintenance – Spacious internal layout allows technicians to access and inspect the unit even during operation; sloped basin and suspended fill make cleaning simple.

- Flexible Transportation & Installation – Modular upper and lower body design enables separate shipping, lowering transport and installation costs.

- Clean & Reliable Operation – Closed-loop design keeps process fluid uncontaminated, reduces chemical treatment needs, and supports stable industrial applications.

Selection Guide

When selecting a BHX tower, engineers should evaluate the required cooling load, site space availability, and water quality. For noise-sensitive projects, optional silencers and low-noise fans are available. In environments with aggressive water conditions, stainless steel or epoxy-coated coils are recommended. The BHX is best suited for projects demanding maximum performance with high reliability.

Development Trend

Future development of BHX towers is focused on sustainability and smart integration. Hybrid systems with dry coolers and adiabatic pre-cooling are being combined with BHX technology to minimize water consumption. Intelligent monitoring systems with IoT connectivity are being adopted for predictive maintenance and real-time efficiency optimization. Advanced materials with anti-fouling properties are also being introduced to extend service life and reduce maintenance costs.

Stop scaling, drifting, and high energy costs TODAY Contact us and get a tailored solution within 24h

Fill out the form below or contact us directly:

Phone: +(86) 18863625021

Email: postmaster@hacstcooling.com

WhatsApp: +(86) 18863625021

Don’t wait — get a quieter, cleaner, and more profitable cooling system as early as tomorrow!

Let me know if you want a more aggressive limited-time offer style, technical-focused version, or one specifically for the North American market — I can refine it further!