guess you like

BHX Combined-Flow Closed-Circuit Cooling Tower – Scalable, Efficient, and Low-Scaling Design

BNX Counterflow Closed Circuit Cooling Tower – High-Efficiency Industrial Heat Exchanger

ZNX Counterflow Evaporative Condenser – Compact, High-Performance Heat Rejection

ZHX Combined Flow Evaporative Condenser – Enhanced Efficiency with Fill-Assisted Heat Transfer

Cooling Coil

Drift Eliminator

PVC Fill

Fan

Spray Nozzle

V-type Air Cooler

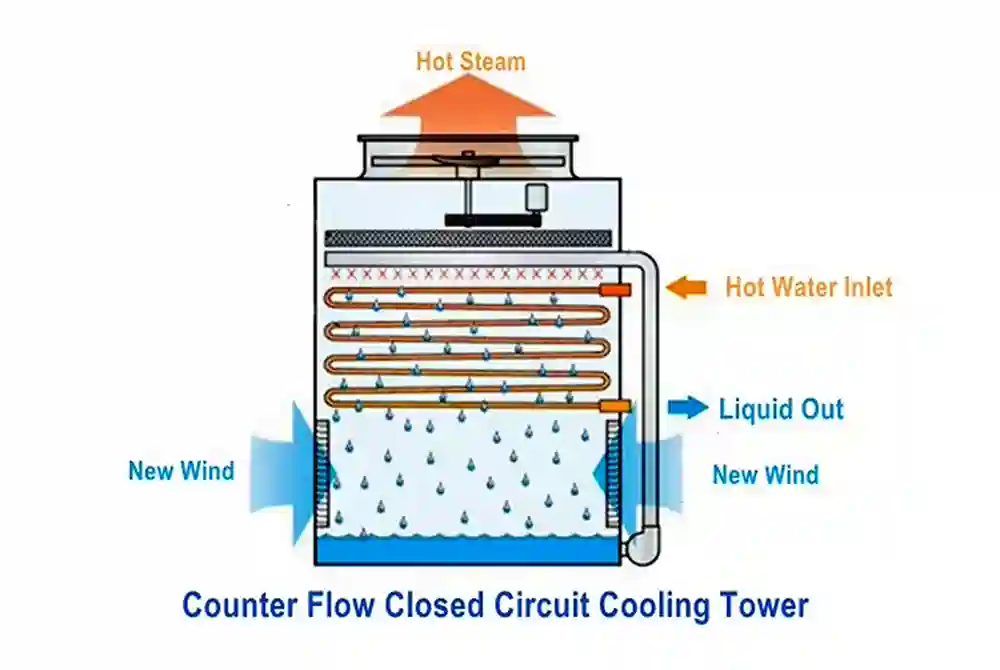

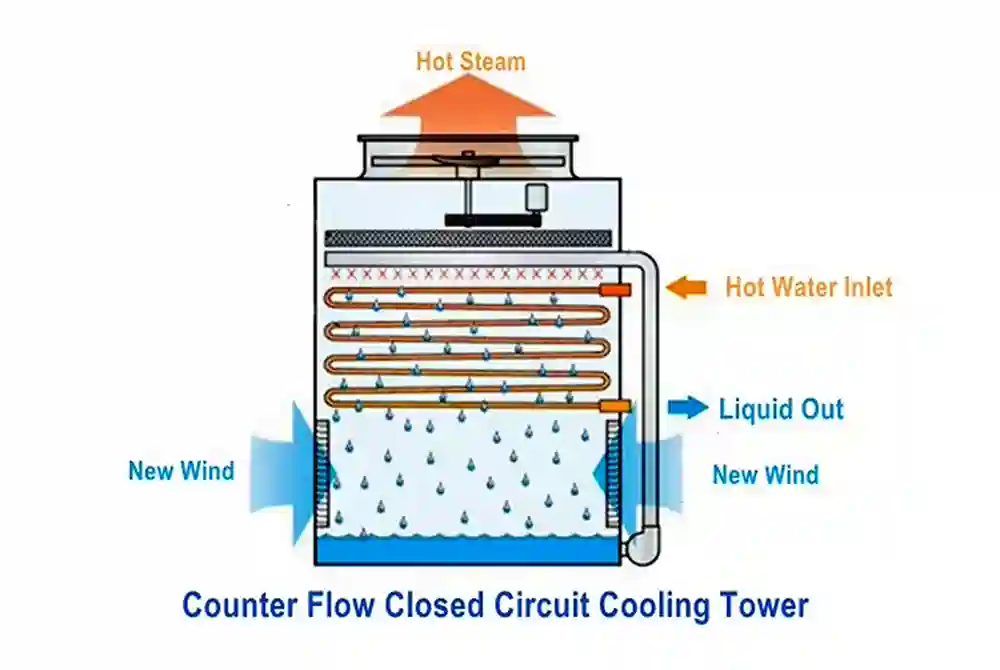

BNX Counter flow Closed Circuit Cooling Tower

Product Overview

The BNX Counterflow Closed-Circuit Cooling Tower is designed to provide efficient and reliable cooling for a wide range of industrial and commercial applications. Unlike open cooling towers, the BNX uses a closed-loop heat exchange system, which prevents contamination of process water and ensures stable thermal performance. Its counterflow design, where air moves upward against the downward spray of water, maximizes the heat transfer efficiency while keeping the system compact.

Working Principle

For BNX series counter flow type closed circuit cooling tower, the fresh air intakes from bottom airinlet, and will become saturated hot air mixed with spraying water as they flow in reverse direction. Theheat will be exhausted out by fans, but the water will be collected to water basin for secondary sprayingby its special designed drif eliminator, As no infill inside, BNX series cooling tower has much space toenlarge its coil unit heat rejection area, the structure is more compact and requires less footprint, Especially, its suitable to the fuid with high temperature.

Applications

- HVAC: Chiller and heat pump cooling for commercial buildings, hospitals, and data centers.

- Industrial Processes: Cooling for manufacturing plants, chemical processing, plastics, and power generation.

- Refrigeration: Suitable for ammonia and CO₂ refrigeration systems in cold storage and food processing plants.

- Energy Sector: Used in cooling loops for renewable energy plants and cogeneration facilities.

Performance & Efficiency

The counterflow design of the BNX ensures maximum utilization of the temperature difference between air and water. By directly exposing the coldest air to the coldest spray water at the top of the tower, the BNX achieves higher cooling efficiency compared to crossflow models of the same size. The closed-circuit configuration eliminates scaling and biological fouling in the process fluid loop, reducing maintenance costs. The BNX is also more water-efficient than open towers, with up to 30% less make-up water required.

Key Advantages

- Compact Design – Fill-free structure with smaller footprint and lower profile, making transport and installation easier, ideal for sites with limited space.

- Closed-Loop Operation – Ensures clean process fluid, prevents contamination, reduces maintenance, and extends equipment life.

- Harsh Environment Adaptability – Enclosed coil structure prevents sand and dust intrusion, widely applied in casting workshops, mining, and other severe conditions.

- High Temperature & Freeze Resistance – No PVC fill, eliminating deformation risks under high temperature and providing better anti-freeze performance in cold climates.

- Flexible Configurations – Multiple coil material options for different water qualities; optional drift eliminators to reduce water loss and protect the environment; high-efficiency axial fans with optional VFD controls for superior energy savings.

Selection Guide

When selecting a BNX tower, engineers should consider cooling capacity requirements, installation footprint, noise restrictions, and water quality. For environments with poor water quality, stainless steel or epoxy-coated coils are recommended. For installations with strict noise limits, low-noise fans or sound attenuation packages are available. The BNX is ideal for users who prioritize water savings, compact design, and system reliability.

Development Trend

Modern BNX towers are integrating smart monitoring systems for real-time performance tracking, predictive maintenance, and energy optimization. Hybrid cooling technologies, such as adiabatic pre-cooling, are being combined with BNX designs to further reduce water consumption. Future advancements focus on noise reduction, corrosion-resistant materials, and modular tower configurations for easier installation and scalability.