guess you like

BHX Combined-Flow Closed-Circuit Cooling Tower – Scalable, Efficient, and Low-Scaling Design

BNX Counterflow Closed Circuit Cooling Tower – High-Efficiency Industrial Heat Exchanger

ZNX Counterflow Evaporative Condenser – Compact, High-Performance Heat Rejection

ZHX Combined Flow Evaporative Condenser – Enhanced Efficiency with Fill-Assisted Heat Transfer

Cooling Coil

Drift Eliminator

PVC Fill

Fan

Spray Nozzle

V-type Air Cooler

Cooling Tower Air Inlet Louver

Overview

The air inlet louver covers the intake openings of a cooling tower. It directs airflow while preventing sunlight, debris, and water splash-out, improving tower efficiency and reducing maintenance.

Role in Cooling Towers

Louvers act as barriers that block unwanted elements from entering the tower. By preventing algae growth (blocking sunlight) and reducing water loss through splash, they enhance cooling tower performance and longevity.

Design Features

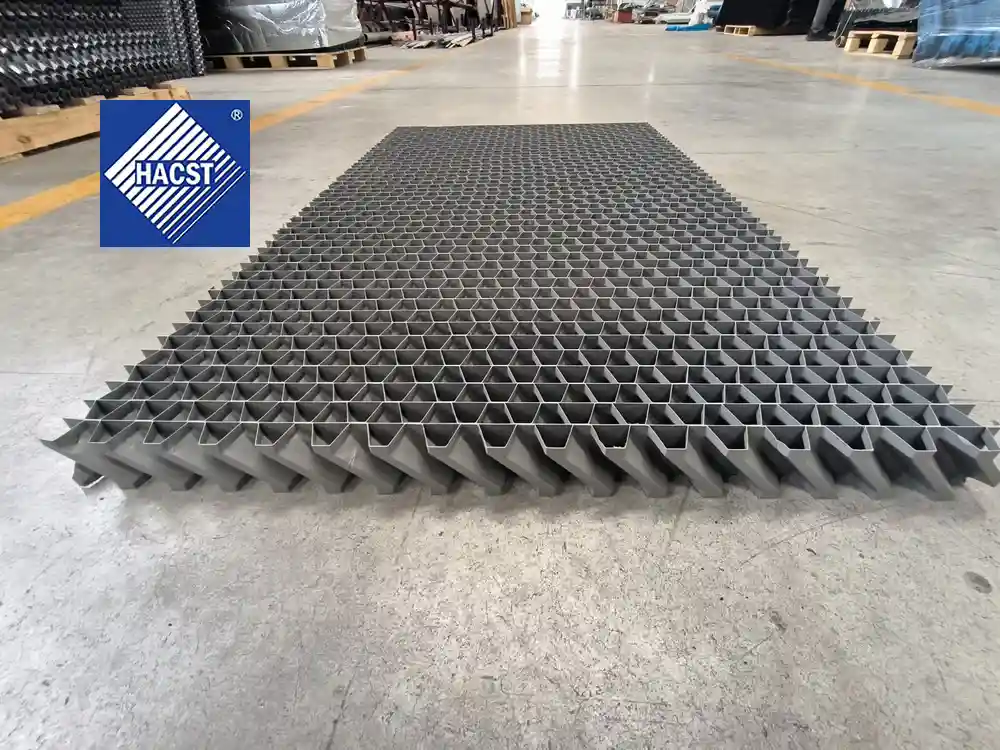

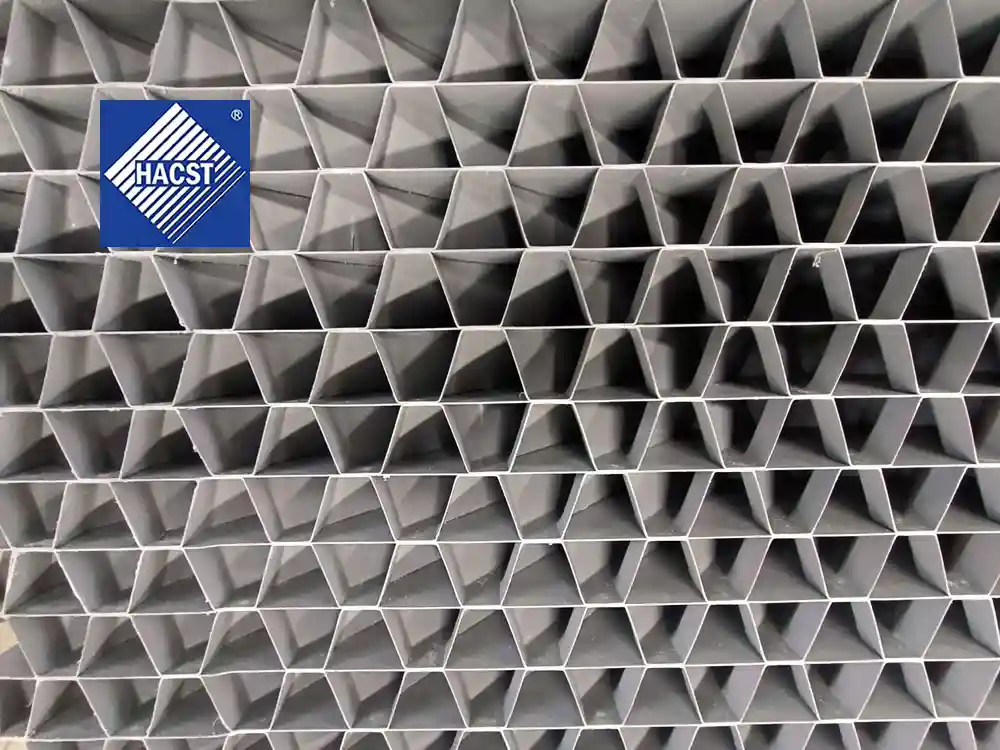

- Chevron Design: Multi-angled blades ensure minimal splash-out while maximizing airflow.

- Horizontal Blade Design: Cost-effective and suitable for smaller towers.

Applications

Air inlet louvers are used across all open and closed cooling towers to protect internal components and improve water efficiency.

How to Select

- For industrial towers → FRP louvers provide durability and corrosion resistance.

- For commercial towers → PVC louvers offer lightweight and cost-effective performance.

- Select chevron design for best splash control and algae prevention.