guess you like

BHX Combined-Flow Closed-Circuit Cooling Tower – Scalable, Efficient, and Low-Scaling Design

BNX Counterflow Closed Circuit Cooling Tower – High-Efficiency Industrial Heat Exchanger

ZNX Counterflow Evaporative Condenser – Compact, High-Performance Heat Rejection

ZHX Combined Flow Evaporative Condenser – Enhanced Efficiency with Fill-Assisted Heat Transfer

Cooling Coil

Drift Eliminator

PVC Fill

Fan

Spray Nozzle

V-type Air Cooler

Counterflow Open Cooling Tower – Compact & High-Performance Cooling Solution

| Parameter | Range / Value |

| Cooling Capacity | 100 – 5,000 kW |

| Water Flow Rate | 50 – 2,500 m³/h |

| Fan Type | High static axial, optionally VFD-controlled |

| Casing Material | Galvanized Steel / FRP / Stainless Steel |

| Fill Media | High-efficiency film or splash fill |

| Drift Loss | ≤ 0.001 % of circulating water |

| Ambient Temp Range | –20 °C to +55 °C |

| Footprint | Compact, vertical design |

| Installation | Modular assembly, easy integration |

Product Overview

The Counterflow Open Cooling Tower by HACST Cooling provides powerful, space-efficient evaporative cooling tailored to demanding industrial and commercial environments. Featuring a vertically opposing airflow and water flow design, it maximizes thermal performance while occupying minimal footprint—ideal for tight spaces or high-load applications.

Key Features & Advantages

- Superior Thermal Efficiency – Pressurized spray nozzles and counter-directional airflow enable enhanced heat transfer via uniform water distribution across the fill .

- Compact Footprint – Vertical design saves ground space, perfect for urban sites or multi-tower installations.

- Reduced Freezing Risk – Spray water breakup and fill configuration improve freeze resistance in cold climates .

- Lower Drift and Sunlight Exposure – Enclosed design limits water drift and protects fill and distribution systems from direct sunlight .

- Ideal for High-Load Environments – Perfect for data centers, power plants, pharmaceuticals, and district cooling where efficiency per footprint matters most.

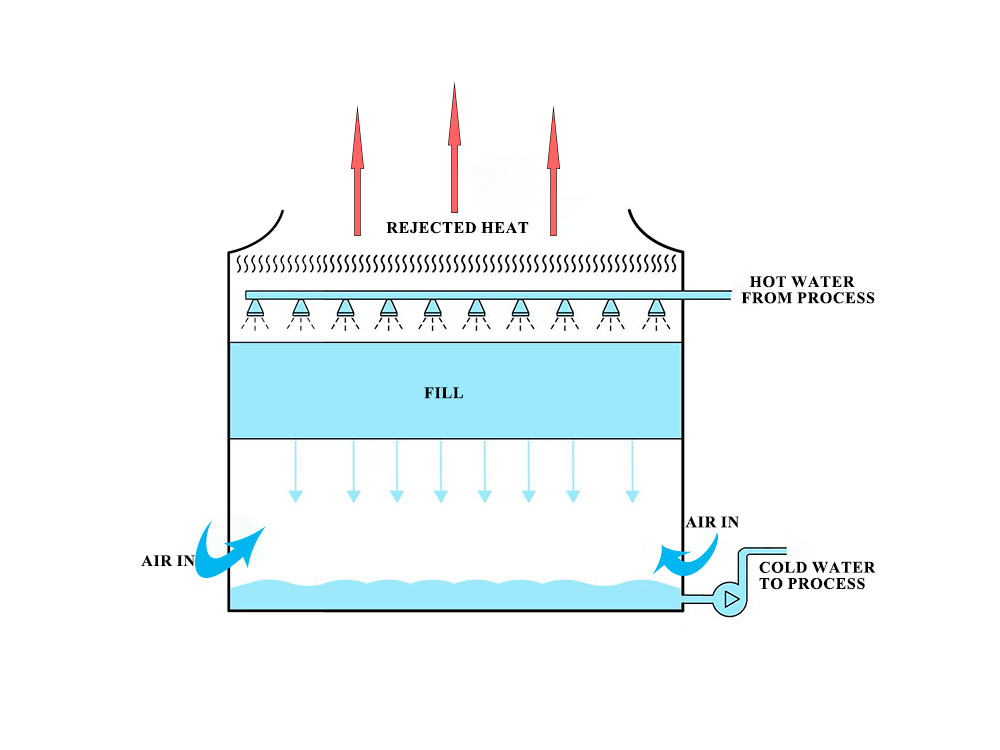

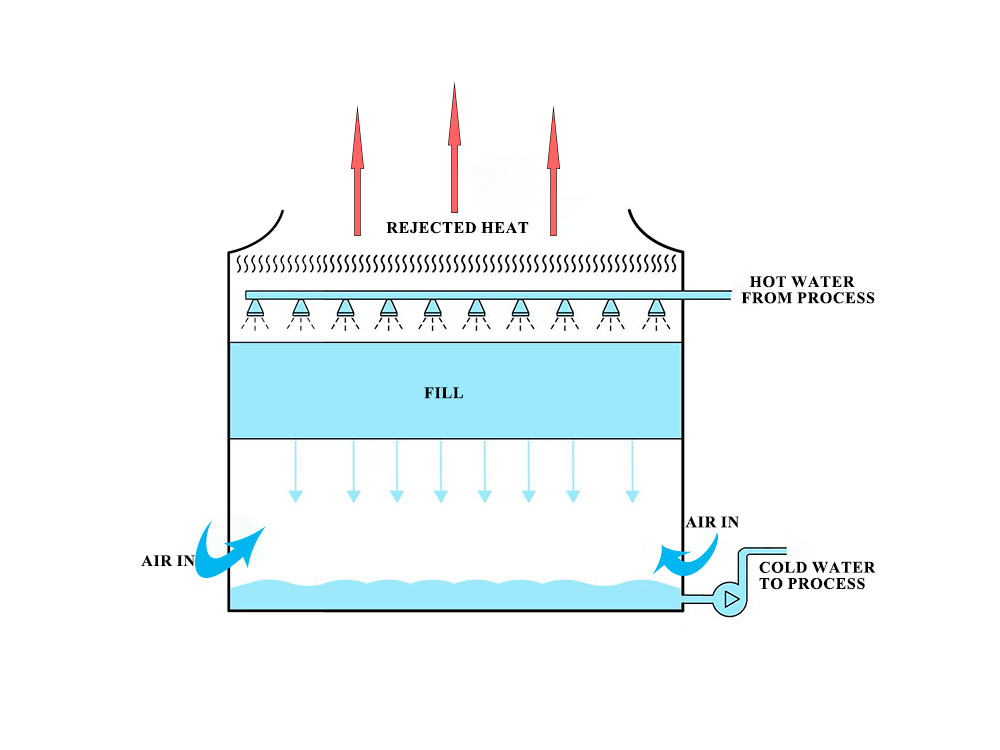

Working Principle

Hot process water is sprayed via high-pressure nozzles downward through the fill media. Meanwhile, air is drawn upward in direct opposition to the water stream. This counterflow arrangement enhances heat exchange efficiency, with cooled water collected at the basin for recirculation.

Applications

Suited for:

- Data Centers — High thermal loads in compact space

- Power & District Cooling — Efficiency-critical environments

- Pharmaceutical & Clean Process Industries — Sensitive applications requiring precise temperature control

- Urban Installations — Where space optimization is vital

Comparison: Counterflow vs. Crossflow

| Feature | Counterflow Open Cooling Tower | Crossflow Open Cooling Tower |

| Thermal Efficiency | Very High — optimized spray and airflow pattern | Moderate — gravity distribution limits performance |

| Footprint | Compact, vertical layout | Larger plan area |

| Maintenance & Access | Limited internal access, may require shutdown | Easy maintenance, often accessible during operation |

| Pump Energy Requirement | Higher — due to pressurized nozzle system | Lower — gravity-fed water distribution |

| Noise & Drift | Moderate — enclosed design suppresses drift | Lower noise, easier access |

| Climate Suitability | Best in warm/hot climates | Better freeze resistance |

Maintenance & Operation Tips

- Regular Inspection of spray nozzles and distribution trays—enclosed design may require periodic shutdown for cleaning .

- Water Treatment to prevent scaling and biofouling; consider microsand filtration to boost cooling efficiency by up to 18% and save energy .

- Fan & Motor Maintenance—ensure proper lubrication and alignment for sustained performance .

- Drift Eliminator Checks—inspect semi-annually for integrity to curb water loss and health risks .

- Legionella Prevention—regular monitoring and biocide application are vital for safe operation .

Why Choose HACST Cooling

- 15+ Years of Technical Excellence — Delivering industrial-grade cooling solutions worldwide

- Certified Quality — Meeting CTI, ISO9001, CE standards

- Global Reach — Projects across 30+ countries

- Full Lifecycle Support — From initial design, commissioning to after-sales service

Get Your Tailored Solution

📩 Contact us with your cooling needs to receive a customized proposal.

Email: hengancooling@gmail.com