guess you like

BHX Combined-Flow Closed-Circuit Cooling Tower – Scalable, Efficient, and Low-Scaling Design

BNX Counterflow Closed Circuit Cooling Tower – High-Efficiency Industrial Heat Exchanger

ZNX Counterflow Evaporative Condenser – Compact, High-Performance Heat Rejection

ZHX Combined Flow Evaporative Condenser – Enhanced Efficiency with Fill-Assisted Heat Transfer

Cooling Coil

Drift Eliminator

PVC Fill

Fan

Spray Nozzle

V-type Air Cooler

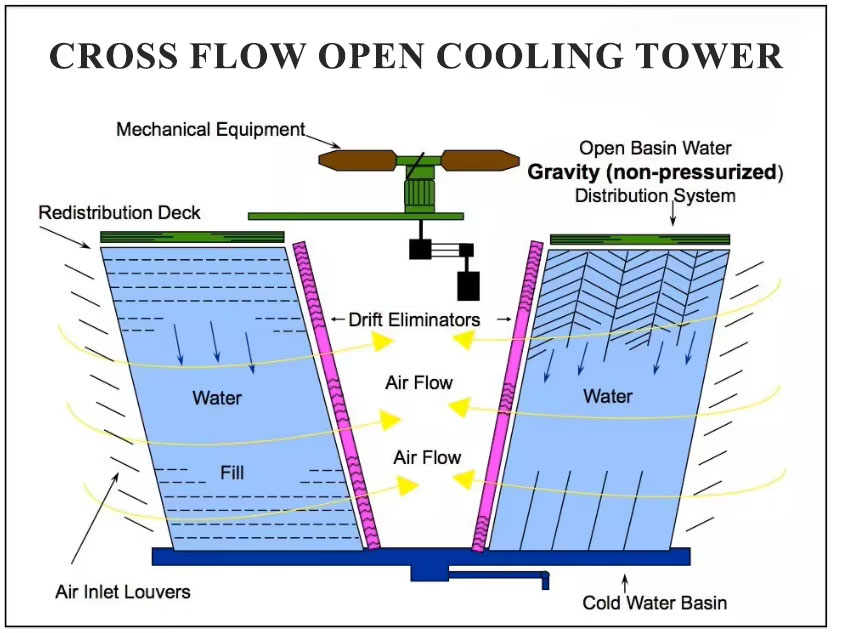

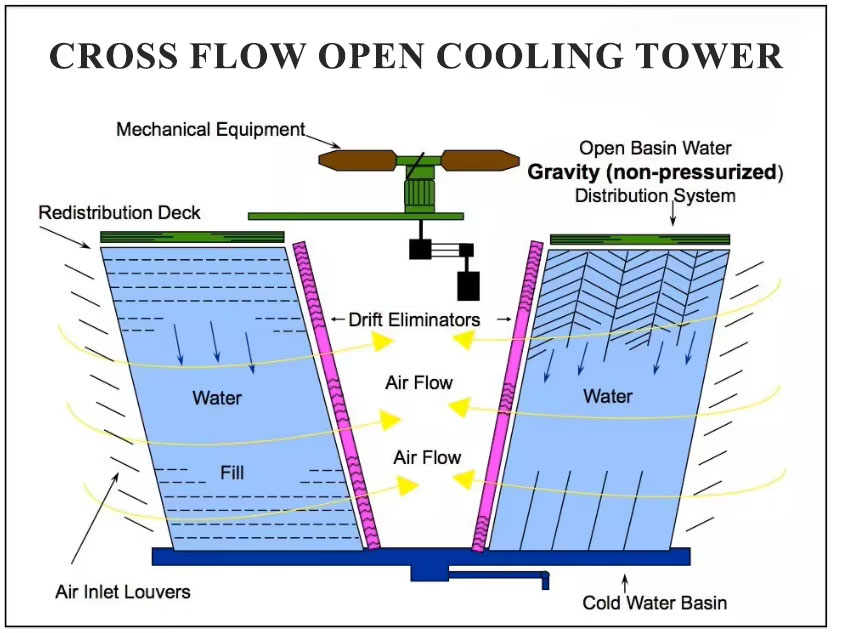

Crossflow Open Cooling Tower – Efficient, Accessible & Reliable Cooling Solution

| Parameter | Range / Value |

| Cooling Capacity | 50 – 3,000 kW |

| Water Flow Rate | 30 – 1,500 m³/h |

| Fan Type | Axial, low-noise, optionally VFD-controlled |

| Casing Material | Galvanized Steel / FRP / Stainless Steel |

| Fill Media Type | High-efficiency PVC or PP splash fill |

| Ambient Temp Range | –20°C to +55°C |

| Footprint | Wider but lower profile compared to counterflow design |

| Installation | Modular assembly with quick-access service platforms |

Product Overview

The Crossflow Open Cooling Tower from HACST Cooling is engineered for high-performance evaporative cooling in demanding industrial and commercial environments. Featuring a streamlined crossflow design, this tower provides energy-efficient cooling with exceptional maintenance accessibility, lower noise levels, and scalable modularity for future expansion.

Key Features & Advantages

- Gravity-Fed Water Distribution – Simplified design eliminates pressurized nozzles, reducing pump energy consumption and enhancing reliability.

- Superior Accessibility & Low Maintenance – Open-side design enables easy inspection and cleaning of internals, significantly reducing downtime.

- Low Operational Noise – Minimal falling water noise and fan placement contribute to quieter functionality.

- Cost-Effective and Energy Efficient – Lower fan power requirements and gravity-based water flow offer long-term operational savings.

- Resilient in Cold Climates – Less prone to freezing compared to counterflow towers, making it ideal for climates with low ambient temperatures.

- Scalable & Modular Design – Easily expanded to accommodate growing heat rejection requirements.

Working Principle

Hot water is evenly distributed from the top basin by gravity over the fill media. Simultaneously, ambient air enters horizontally through the side louvers and passes across the water stream, promoting evaporation and effective heat transfer. Cooled water collects in the basin for recirculation.

Crossflow Open Cooling Tower woking principle

Applications

Ideal for:

- HVAC systems in commercial buildings

- Chemical & Petrochemical cooling processes

- Food & Beverage production lines

- Textile & Pulp & Paper industries

- Jacket water cooling for compressors and engines

- Data centers needing low-noise cooling solutions

Crossflow vs. Counterflow: Quick Comparison

| Feature | Crossflow Open Cooling Tower | Counterflow Cooling Tower |

| Efficiency | Moderate but sufficient for most applications | Higher thermal performance, smaller footprint |

| Maintenance | Very easy access, low downtime | More complex internal access, higher maintenance |

| Energy Use | Lower fan and pump energy consumption | Higher pump head and fan energy |

| Noise Level | Low | Relatively higher due to water fall and enclosed design |

| Climate Suitability | Better for cold climates; less freeze-prone | Higher efficiency in warmer climates |

Best for: Applications where serviceability, low noise, and balanced performance are needed.

Counterflow towers are preferable when maximum cooling efficiency and compact footprint outweigh maintenance convenience.

Maintenance & Operation Tips

Clean fill and basin regularly to avoid buildup and maintain efficiency.

Install filtration systems to reduce fouling and scale formation, boosting energy performance by up to ~18% per study.

Use anti-algae and biocide treatments proactively, especially where sunlight exposure is high.

Why Choose HACST Cooling

15+ Years of Expertise in delivering industrial cooling solutions tailored to your needs

Global Footprint – Trusted in over 30 countries

Certified Quality – CTI, ISO9001, CE & more

Comprehensive Support – From engineering design to installation and after-sales service

Contact Us for a Custom Solution

📩 Tell us your cooling requirements to receive a personalized quote.

Email: hengancooling@gmail.com