guess you like

BHX Combined-Flow Closed-Circuit Cooling Tower – Scalable, Efficient, and Low-Scaling Design

BNX Counterflow Closed Circuit Cooling Tower – High-Efficiency Industrial Heat Exchanger

ZNX Counterflow Evaporative Condenser – Compact, High-Performance Heat Rejection

ZHX Combined Flow Evaporative Condenser – Enhanced Efficiency with Fill-Assisted Heat Transfer

Cooling Coil

Drift Eliminator

PVC Fill

Fan

Spray Nozzle

V-type Air Cooler

Industrial Cooling Tower – High-Efficiency Modular Cooling Solution

| Parameter | Value Range |

| Cooling Capacity | 100 – 5,000 kW |

| Water Flow Rate | 50 – 2,500 m³/h |

| Fan Type | Axial, low-noise, variable speed |

| Casing Material | Galvanized Steel / Stainless Steel / FRP |

| Fill Media | High-efficiency PVC or PP fill |

| Drift Loss | ≤ 0.001% of circulating water |

| Ambient Temp Range | –20°C to +55°C |

| Installation Type | Modular on-site assembly |

Product Overview

The Industrial Cooling Tower from HACST Cooling is designed for large-scale heat rejection in heavy-duty industrial applications. With a robust modular structure, energy-saving airflow design, and corrosion-resistant materials, it delivers long-term reliable performance in harsh operating environments.

Our towers are suitable for continuous operation under extreme climates, while minimizing water and energy consumption. Each unit can be customized to meet your project’s capacity, footprint, and environmental requirements.

Key Features & Advantages

- High Heat Rejection Efficiency– Optimized fill media and airflow design ensure maximum cooling performance.

- Modular Design– Easy transportation and on-site assembly, scalable to meet future capacity needs.

- Corrosion-Resistant Materials– Galvanized steel, stainless steel, or FRP construction for extended service life.

- Energy & Water Saving– Advanced drift eliminators and fan control systems reduce operational costs.

- Low Maintenance– Easy-access panels and simplified water distribution system for quick inspection and servicing.

- Custom Engineering– Adaptable to different water quality, temperature range, and industrial process requirements.

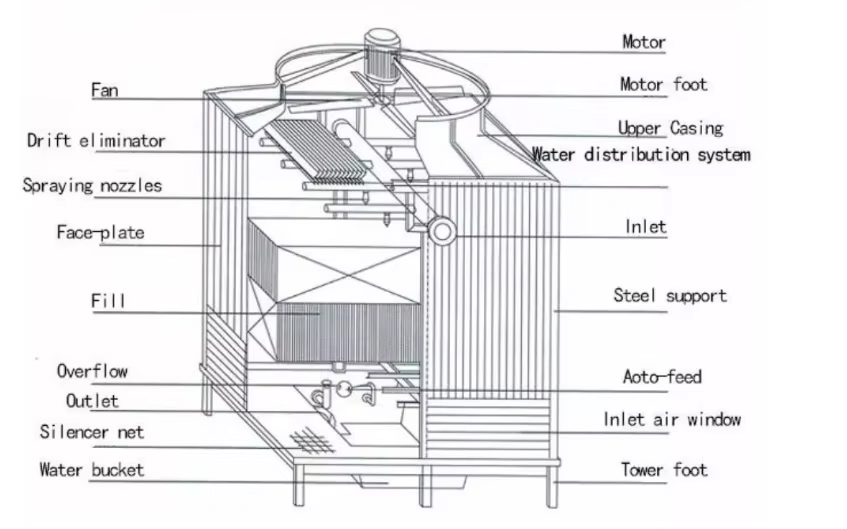

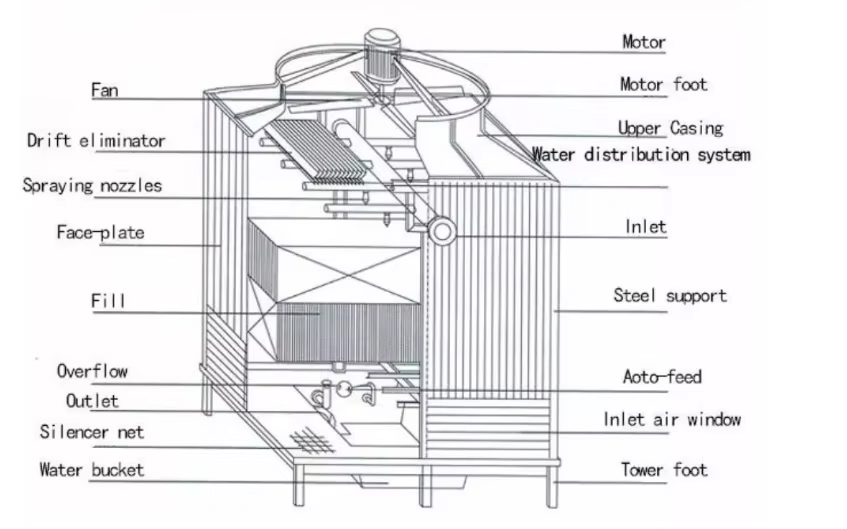

Working Principle

Hot process water enters the cooling tower and is evenly distributed over the fill media. As air is drawn upward by the axial fan, water is cooled through direct contact with the air stream, allowing partial evaporation to remove heat. The cooled water collects in the basin for recirculation, while drift eliminators minimize water loss.

Applications

Our industrial cooling towers are used across various industries, including:

- Steel & Metal Processing Plants

- Power Generation Facilities

- Chemical & Petrochemical Plants

- Food & Beverage Production

- HVAC & District Cooling Systems

- Data Centers

Comparison: Industrial Cooling Tower vs Other Types

| Feature | Industrial Cooling Tower | Open Cooling Tower | Closed Circuit Tower |

| Heat Rejection Capacity | Very High | Medium to High | Medium |

| Water Consumption | Medium | High | Low |

| Maintenance | Moderate | High | Low to Moderate |

| Corrosion Protection | High | Low to Medium | Very High |

| Best Use Case | Heavy Industry | HVAC / General Use | Clean Process Cooling |

Maintenance & Service Tips

Inspect and clean fill media every 3–6 months.

Monitor water quality and perform chemical treatment to prevent scaling.

Lubricate fan and motor bearings as per manufacturer’s schedule.

Check drift eliminators and replace if damaged.

Ensure fan belts (if applicable) are tensioned and aligned.

Get a Quote

📩 Contact us today to discuss your project requirements and receive a tailored cooling solution.

Email: hengancooling@gmail.com