guess you like

BHX Combined-Flow Closed-Circuit Cooling Tower – Scalable, Efficient, and Low-Scaling Design

BNX Counterflow Closed Circuit Cooling Tower – High-Efficiency Industrial Heat Exchanger

ZNX Counterflow Evaporative Condenser – Compact, High-Performance Heat Rejection

ZHX Combined Flow Evaporative Condenser – Enhanced Efficiency with Fill-Assisted Heat Transfer

Cooling Coil

Drift Eliminator

PVC Fill

Fan

Spray Nozzle

V-type Air Cooler

PVC Cooling Tower Fill Media

Overview

HACST® manufactures a complete range of PVC, CPVC, and PP cooling tower fill media designed for high thermal performance, durability, and compatibility with all major cooling tower brands, including Marley, BAC, Liangchi, Kingsun, Brentwood, Kuken, Hamon, and others.

Cooling tower fill is the core heat-exchange component responsible for forming water films or droplets, increasing the contact area with air, and enabling efficient evaporative cooling. High-quality fill media directly improves cooling capacity and reduces energy consumption.

Role in Cooling Towers

- Heat Transfer Enhancement: Corrugated or grid structures create large surface areas for evaporation.

- Improved Water Distribution: Develops uniform water films or droplets for balanced air–water contact.

- Maximized Cooling Efficiency: Determines up to 70–80% of overall cooling tower performance.

- Supports Crossflow & Counterflow Designs: Suitable for industrial, HVAC, and high-load cooling environments.

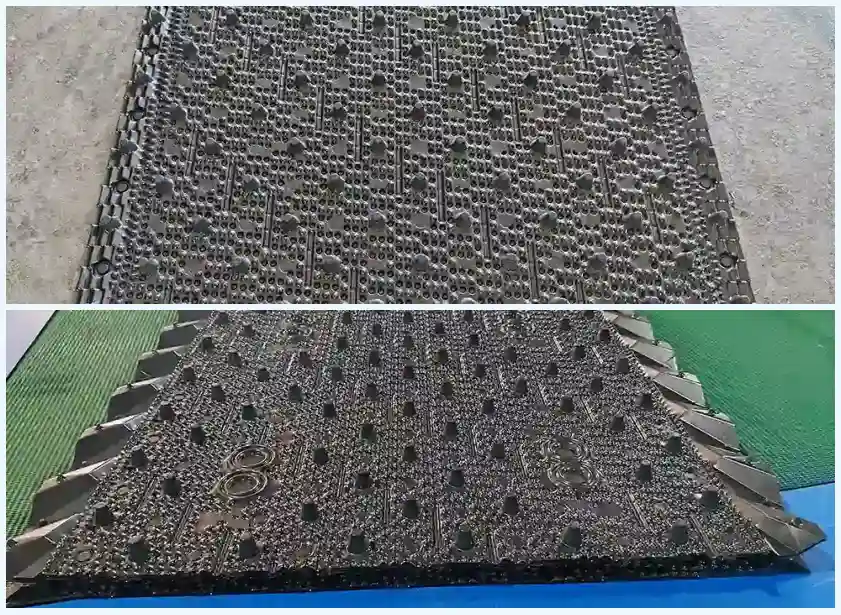

Materials

HACST uses high-grade polymers to ensure long service life and stable cooling performance.

| Material | Temperature Resistance | Features |

|---|---|---|

| PVC | 50–60°C | High efficiency, widely used, cost-effective |

| CPVC | 90–100°C | For high-temperature industrial cooling |

| PP | 80–95°C | Chemical-resistant, ideal for dirty water |

Types of Cooling Tower Fill

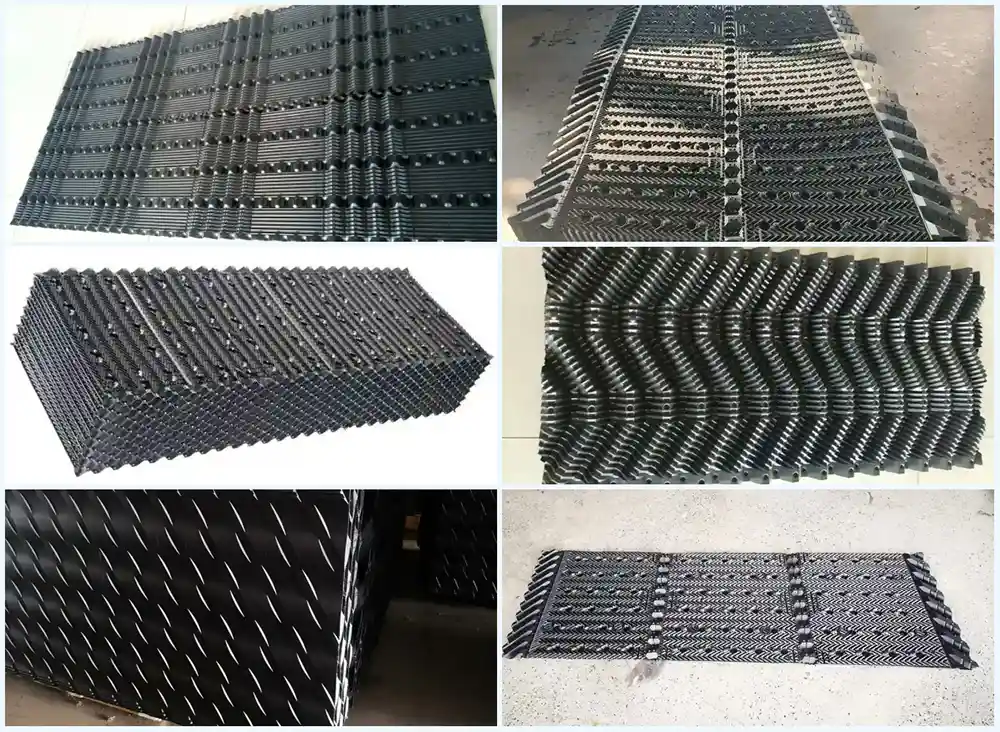

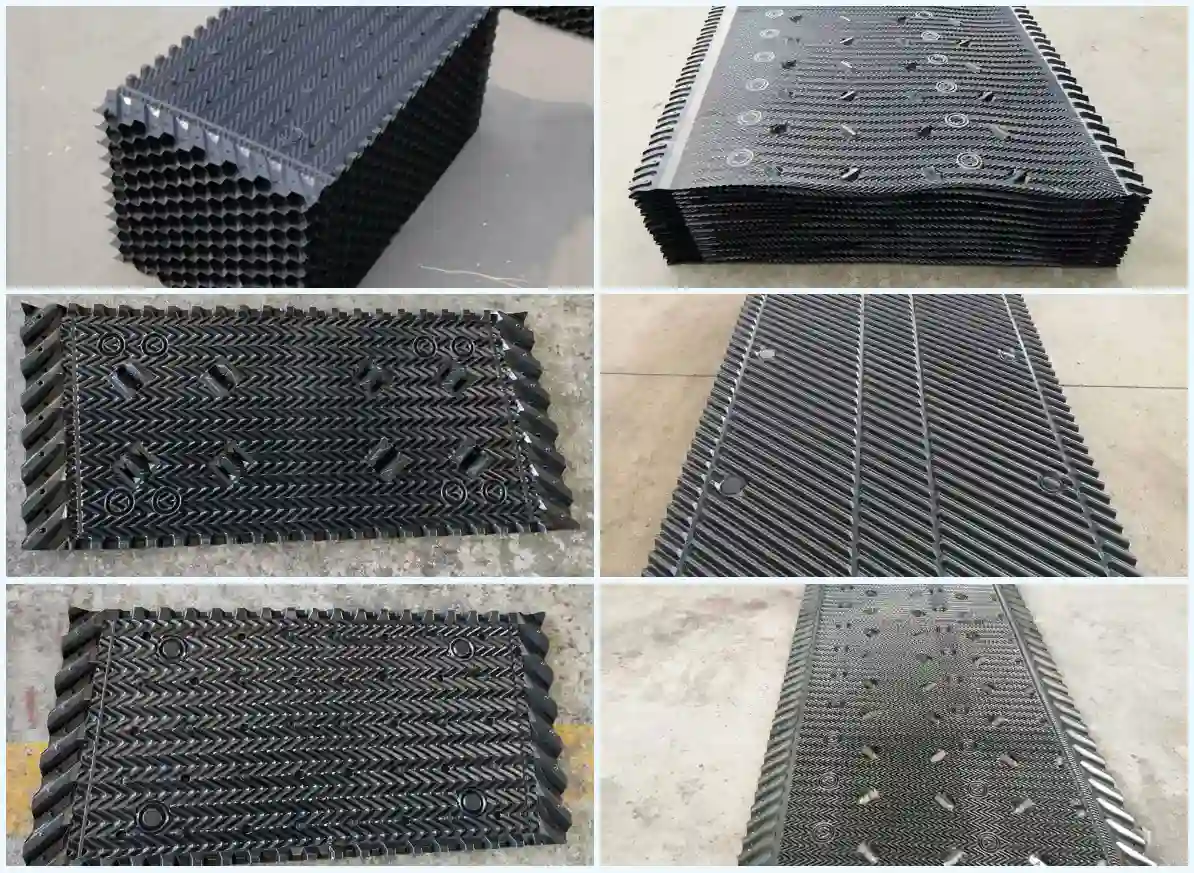

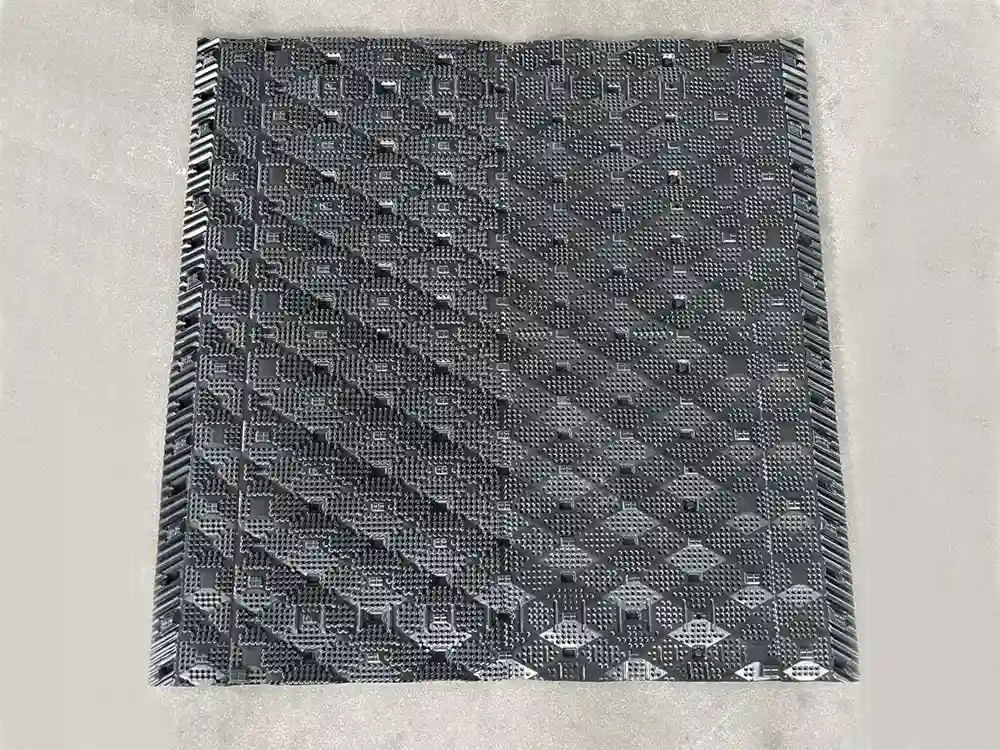

A. Film Fill (High-Efficiency Thin Film Type)

Designed for clean water applications requiring maximum thermal performance.

- Marley Type (F-001–F-010): 19mm spacing, 610–1520mm width.

- BAC Type: Optimized corrugated sheets for high cooling efficiency.

- Liangchi Type (F-011–F-012): 20mm sheet spacing.

- Kuken Type (F-013–F-014): 15/20mm spacing for Japanese cooling towers.

- Kingsun Type (F-017–F-019): 12–19mm spacing, 300–610mm width.

- Brentwood Type (F-020–F-022): Includes S-type & turbidity-resistant designs.

- Hamon Type (F-023–F-024): 305–610mm width for European cooling systems.

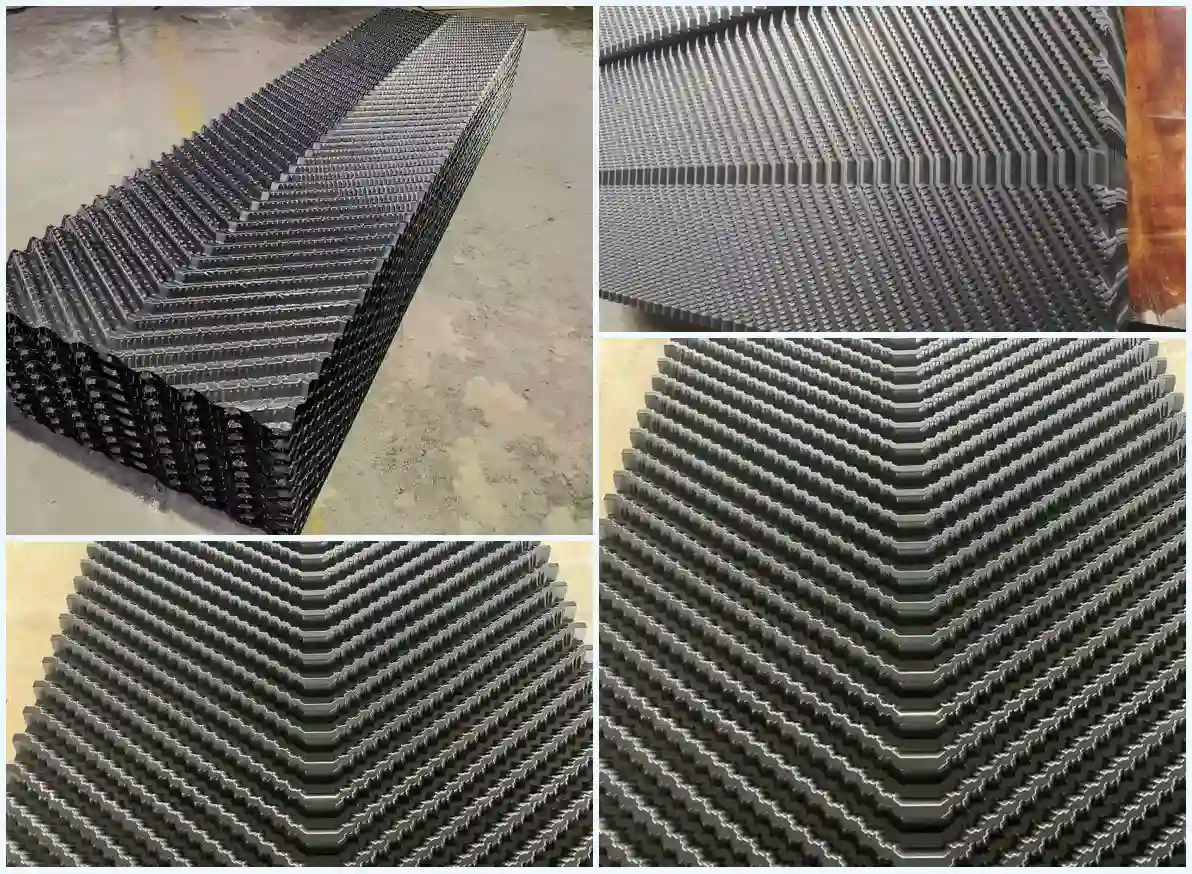

B. Special Structured Film Fill

- S-Type Fill (F-027): High turbulence and mixing effect.

- Spindle Fill (F-026): Suitable for crossflow towers.

- Round Cooling Tower Fill (F-028): 650–810mm diameter.

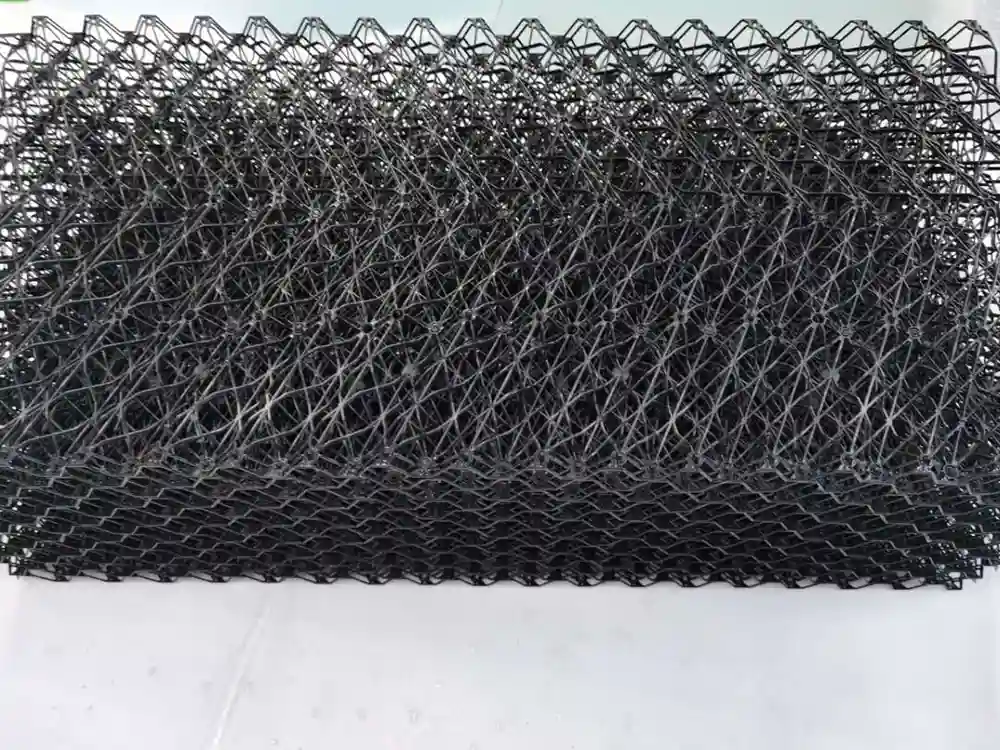

C. Splash Fill (For Poor Water Quality)

- PP Grid Fill (F-029): Strong chemical resistance and anti-fouling ability.

- PP Trickle Fill: Suitable for high-temperature or polluted water conditions.

Advantages of HACST® Fill Media

- Hydrophilic surface improves water distribution by 15–20%.

- High structural strength from vacuum forming and hydraulic compression.

- Excellent UV resistance, anti-aging and long lifespan.

- Easy installation, cutting, and replacement for all major brands.

- PP and CPVC options available for high-temperature and corrosive environments.

Available Specifications

- Length: 400–1800mm (customizable)

- Width: 225–1520mm

- Sheet Spacing: 12 / 15 / 16 / 18 / 19 / 20 / 33 / 61 mm

- Thickness: 0.3–1.0 mm

- Colors: Black, grey, blue, transparent

Applications

Cooling tower fill media is widely used in:

- HVAC & commercial cooling

- Petrochemical plants

- Power stations

- Steel & metallurgy

- Food processing (chicken, meat, seafood)

- Plastic extrusion & injection cooling

- Mining & coal washing

- Industrial refrigeration systems

- Evaporative condensers

- Data centers

Installation Guide

- Remove old fill and clean internal tower structure.

- Check beam supports and spacing before installation.

- Install blocks layer-by-layer in correct airflow direction.

- Fix sheets using PVC welding or nylon tie rods.

- Run water distribution test to confirm uniform flow.

Quality Control

- Raw material purity test

- Thickness measurement & spacing calibration

- High-temperature deformation test

- UV aging resistance test

- Pressure drop & airflow performance test

Why Choose HACST®?

- Factory-direct manufacturing with strict QC systems

- Exported to 100+ countries worldwide

- Fully compatible with all major cooling tower brands

- Fast delivery & large production capacity

- Professional engineering team supporting OEM/ODM projects