guess you like

BHX Combined-Flow Closed-Circuit Cooling Tower – Scalable, Efficient, and Low-Scaling Design

BNX Counterflow Closed Circuit Cooling Tower – High-Efficiency Industrial Heat Exchanger

ZNX Counterflow Evaporative Condenser – Compact, High-Performance Heat Rejection

ZHX Combined Flow Evaporative Condenser – Enhanced Efficiency with Fill-Assisted Heat Transfer

Cooling Coil

Drift Eliminator

PVC Fill

Fan

Spray Nozzle

V-type Air Cooler

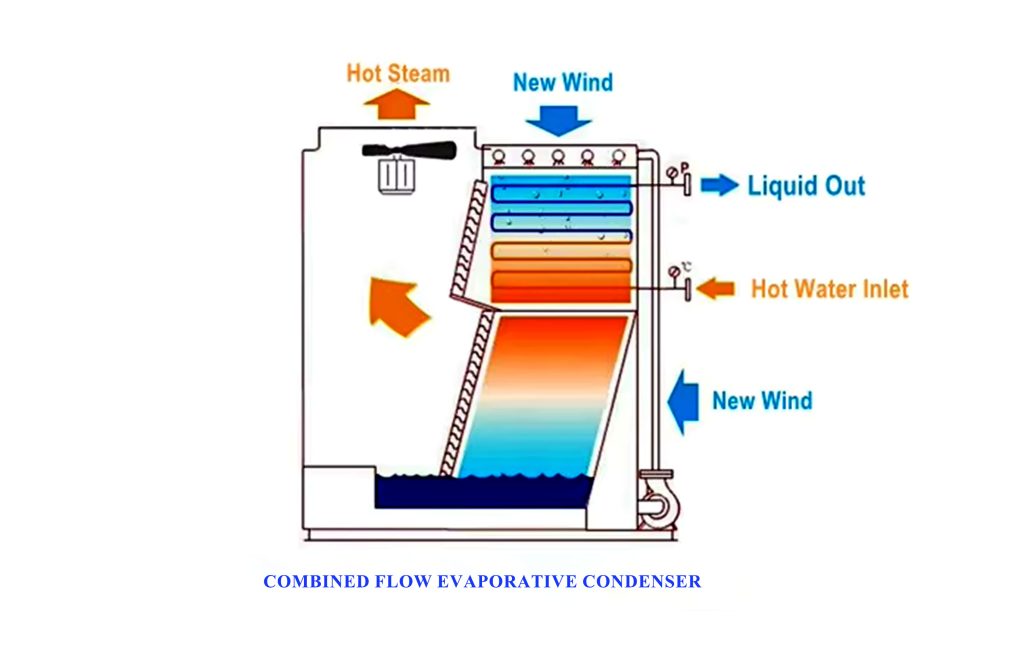

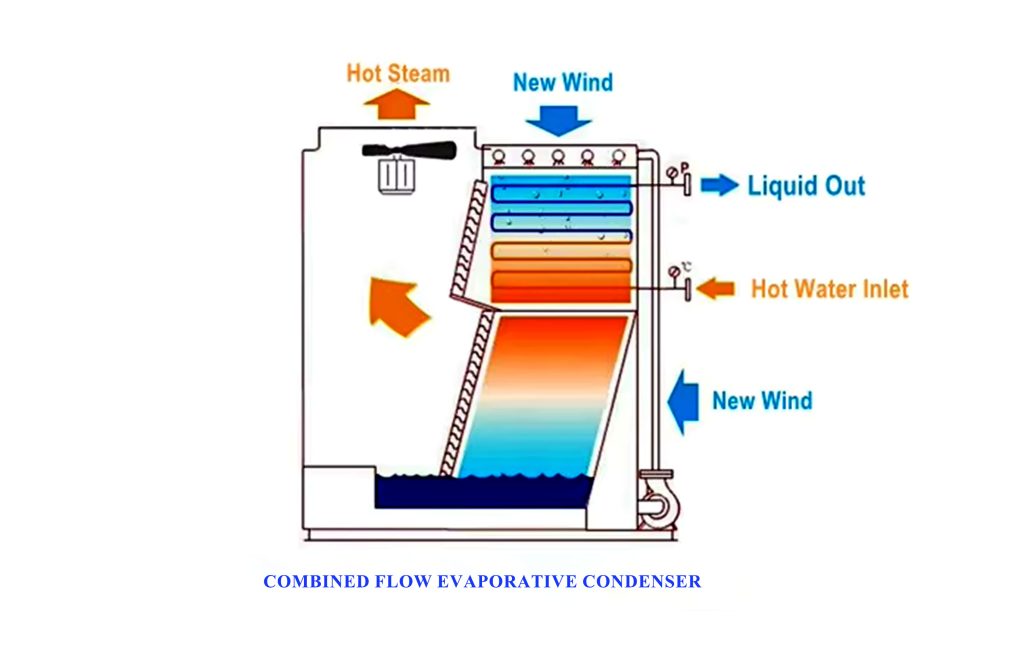

ZHX Combined-Flow Evaporative Condenser

Product Overview

ZHX merges crossflow and counterflow air paths. Spray water simultaneously wets the coil and passes through a dedicated fill pack. Horizontal air intake improves wetting uniformity, while vertical counterflow across the coil boosts LMTD. The result is a lower approach temperature at a given fan power, ideal for large refrigeration plants pursuing best-in-class compressor efficiency.

Working Principle

In the 2HX series, refrigerant condenses inside the closed coil while recirculated water is sprayed over the coil to enhance heat transfer. At the same time, part of the spray water passes through PVC fill, which increases contact area, pre-cools the incoming air, and lowers water temperature. Fresh air enters from both the sides (crossflow) and bottom (counterflow), then mixes with spray water as it flows upward, carrying heat away with the axial fans.

This dual-path airflow ensures stable performance under fluctuating loads and varying ambient conditions. Collected water is returned to the basin through drift eliminators for recirculation, ensuring low water consumption and efficient, continuous operation.

Why Combined-Flow?

- Excellent Heat Exchange – Dual airflow paths and the combination of coil and PVC fill maximize contact efficiency, avoid dry spots and scaling, and deliver superior thermal performance.

- Stable & Efficient Operation – Crossflow segments improve water distribution, while VFD control enables high efficiency even at partial load.

- Compact & Practical Design – Higher cooling capacity per footprint than single-flow designs; modular upper and lower body structure simplifies transport and installation.

- Easy Maintenance – Spacious internal layout allows on-site inspection during operation, while suspended PVC fill and a sloped basin floor toward the drain make cleaning fast and convenient.

Applications

- Large cold storage campuses and food logistics hubs.

- Dairy, meat processing, beverage and brewery lines.

- Petrochemical and specialty chemical plants with variable loads.

Sizing & Selection

Define heat of rejection at design, wet-bulb, target condensing temperature, and permissible noise. ZHX is preferred when approach ≤5 K is desired without oversizing. Select coil material per water chemistry; specify low-speed axial fans with VFD for acoustic-sensitive zones. Where height is constrained, ZHX yields more capacity per footprint than pure crossflow.

Energy & Water Efficiency

The fill path pre-cools air, reducing fan power for a given condensing pressure. Water use is optimized via cycles-of-concentration control, side-stream filtration, and drift eliminators. Compared with air-cooled condensers, ZHX can deliver double-digit compressor kWh savings annually, particularly in warm, humid climates where wet-bulb leverage is significant.

Materials & Hygiene

Coil: HDG standard, stainless optional. Casing: galvanized or pre-painted steel; SS for coastal/chemical sites. Drift eliminators limit carryover; accessible basins and removable panels facilitate sanitation programs aligned with industrial hygiene best practices.

Controls & Options

- Integrated condensing pressure reset and floating head pressure strategies.

- Ambient/wet-bulb tracking for fan VFD and spray staging.

- Winter duty kits: basin heaters, smart drain, freeze protection.

- Acoustic packages: low-tip-speed blades, discharge silencers.

Installation & Maintenance

Provide clear side-air inlets and top discharge. Ensure structural plinth, vibration isolation, and accessible service sides. Commission with nozzle verification, eliminator inspection, and control loop tuning. Quarterly tasks: water quality checks, blowdown calibration, basin sediment removal, coil integrity checks.

Development Trends

ZHX is at the forefront of hybridization—pairing with adiabatic dry sections for shoulder seasons, and employing advanced polymer fills to resist fouling. Digital condition monitoring and cloud analytics are becoming standard to maximize uptime and minimize lifecycle cost.